You’ve probably been warned not to play with fire. But aside from fire, there is another thing that you should not play with— electricity.

Electricity poses dangers including burns, shocks, and even death. Thus, it is no joke if dealing with electricity is part of your everyday work.

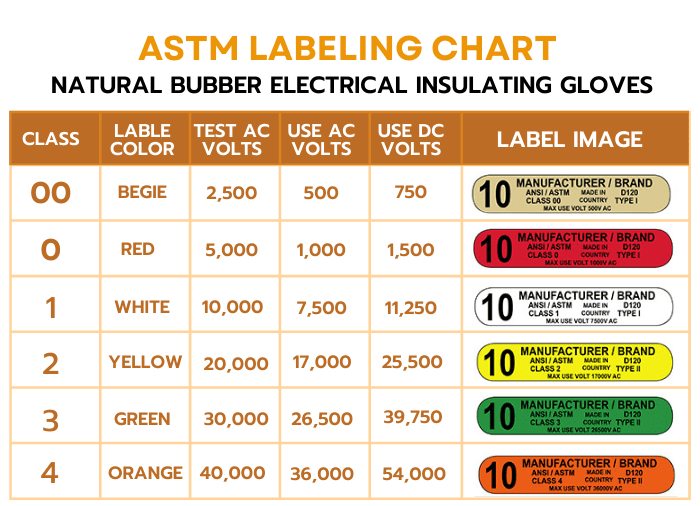

Thus, the Occupational Safety and Health Administration (OSHA) requires the use of electrical gloves for electric work. Depending on the electricity’s voltage, there are different classes of electrical gloves to choose from, including 00, 0, 1, 2, 3, and 4.

Table of Contents

Types of Classes

The Occupational Safety and Health Administration (OSHA) requires electric gloves for when dealing with anything higher than 50V. They laid out the required electrical safety gloves specifications.

OSHA also developed the electrical gloves class chart chart to determine what rating of high voltage insulating gloves can be used. Based on the chart, electrical glove ratings range from 00 to 4, with each class determining the maximum voltages it can withstand.

Here are the different classes and their corresponding voltage rating:

| Class | Maximum AC Voltage | Maximum DC Voltage |

| Class 00 | 500V | 750V |

| Class 0 electrical gloves | 1000V | 1,500V |

| Class 1 | 7,500V | 11,250V |

| Class 2 | 17,000 | 25,500V |

| Class 3 rubber gloves | 26,500V | 39,750V |

| Class 4 | 36,000V | 54,000V |

Components

When it comes to gloves for dealing with electric, you’ll come across three main types.

1. Rubber gloves

These are the electrical rated gloves, meaning they’re the ones which provide real insulation against electric hazards. Hence, they’re classified according to the maximum level of voltage they can protect you against.

2. Liner gloves

Usually made of cotton, liner gloves are worn under rubber gloves in order to lessen chafing and discomfort caused by the rubber. Liner gloves are also ideal for heat retention during winter.

3. Leather gloves

Leather gloves go over the rubber electrical ones. These gloves shield the rubber from various kinds of damage, provided that they both share the same class. Note that leather gloves themselves offer no protection against electrical shock and, thus, should not be worn alone.

Sizes

Aside from coming in with different classes, electrical gloves also come in different sizes. Identifying your right size is important to ensure that the gloves are not too tight, which may restrict blood circulation, or too loose, causing the gloves to slip off.

When it comes to the US measurement system, glove sizes range from extra-small (XS) up to double extra-large (XXL). However, sometimes, you’ll see gloves being referred to by number – ranging from 6 to 11 – these are the EU size. Rest assured that while the names may be different, the glove size are still the same.

In order to determine your glove size, all you have to do is measure your dominant hands’ length (the base of the hand to the middle finger’s tip) and width (circumference of the palm, right under the first knuckles).

Then, you may choose your size based on your measurements:

| Size | Width (inches) | Length (inches) |

| Extra Small (XS)(EU—6) |

6-7 | 6 5/16 |

| Small

(S) (EU—7) |

7-8 | 6 ¾ |

| Medium

(M) (EU—8) |

8-9 | 7 3/16 |

| Large

(L) (EU—9) |

9-10 | 7 9/16 |

| Extra Large

(XL) (EU—10) |

10-11 | 8 1/6 |

| Double Extra Large

(XXL) (EU—11) |

>11 | 8 7/16 |

Testing and Programs

To ensure their quality and functionality, OSHA mandates that electrical insulated gloves for electrical work be tested periodically.

According to OSHA’s testing requirements, the first test shall be done when they are first issued for service. Afterwards, they will undergo repeat testing every six months, or after each use without the protective leather gloves.

If the gloves are found defective or have suspicious insulating value, they shall be tested twice. The first one would be after their repair, and the second is after using them without protectors.

Aside from the periodic testing, it is also recommended that electric gloves be visually inspected every day. The inspection is to detect the following:

- Holes, abrasions, cuts. You can easily check for holes and cuts by do the air testing – blowing air into the hole to see if there’s any leak.

- Visible change in texture – do the gloves feel harder, or do they lose their elastic nature?

- Degeneration due to ozone exposure and mechanical stress

- Foreign objects, such as tiny rocks, needles, lodged into the glove

Once any of the defects are detected, the gloves in question shall be pulled out and cannot be used.

Frequently Asked Questions

Types of Electrical Gloves

Aside from the classes, there are also two types of electrical insulating gloves. These types are determined by the glove materials’ resistance to ozone.

- Type I Electric Gloves

Type I gloves are those made of natural rubber. Rubber is non-resistant to ozone, which will cause it to crack when exposed to it.

- Type II Electric Gloves

On the other hand, Type II gloves are ozone-resistant. Their integrity is not compromised in high levels of ozone as they are made of synthetic rubber.

What are Class 0 gloves used for?

Class 0 voltage rated gloves are the gloves for working with electricity that is no higher than 1000V (AC) and 1,500 (DC).

Is 1000V dangerous?

Although 1000V is only considered as low voltage, this does not mean that it is not high-risk. Coming into contact with it can result in deep burns. This is why you need to wear electricians gloves 1000V (Class 0), even when dealing with such a low voltage.

Additionally, the Ohm’s Law dictates that the voltage is not the direct cause of harm, but the current. However, the voltage plays a part in weakening one’s resistance to the current.

Thus, if the voltage significantly weakens the body’s resistance, the flow of the current will likewise be significant. In such cases, voltages even lower than 1000V can be life-threatening if the resistance is already weak.

Conclusion

A pair of insulated gloves for electrical work does not only protect your hands. It protects your whole life.

After reading this guide, you may find that determining the appropriate class of electrical gloves is easy. However, due care and diligence in ensuring that their protective qualities are maintained and not compromised are long-term commitments.

Veronica is our content editor. She is a talent in delivery. Her main work is editing and writing articles that are both informative and simple to follow. She is in charge of synthesizing our understanding of what personal protection equipment (PPE) is needed in each job, how to best apply it, and how to visualize that equipment.