How do cut-resistant gloves work? The magic lies in their supreme yarn. Safety cutting gloves are made with machine-knitted and cut-resistant materials that can be 15 times stronger than steel.

Manufacturers construct the yarn with a core and outer wrap of fibers to enhance its resistance. These fibers can prevent extreme cut hazards, protecting your hands even when you accidentally touch the sharp edges of glass and blades.

It’s simple to imagine how a knife can’t cut through steel, but the scenario might raise several questions:

- What about flexibility and comfort?

- Does the glove’s sturdy fabric compromise its dexterity?

- What materials can protect against severe hazards?

Read below for more answers.

Table of Contents

Cut-Resistant Gloves: How Do They Work?

Traditionally, knife safety gloves can protect your hands because of their cut-resistant fabric, which consists of an inner core and an outer wrap. It’s like taking a vigorous material and adding a robust core to make it even stronger. So, what are cut-resistant gloves made of?

1. The outer wrap

The external layer is from HPPE (high-performance polyethylene) or Aramid. You might be familiar with the brand names Dyneema®, Kevlar®, and SuperFabric®. These are major manufacturers of cut-proof materials.

Kevlar® is lightweight and flexible but has lower cut resistance. Dyneema® is 10 to 15 times stronger than steel and 40% stronger than Kevlar®. SuperFabric® has the highest ratings and retains its resistance and grip under wet or oily conditions.

Another superior cut-resistant material is metal mesh. It is like chainmail made of rings of stainless steel. A sharp knife won’t penetrate such metal structures. The material is also easier than polyester to clean and sanitize.

On top of that, the loose-knitted construction allows the metal rings to move around when contacting a sharp edge. The rolling actions help absorb the impacts and make it more difficult to cut through. The mechanism is similar to how it would be harder to run a saw through a loose rope than a tight one.

2. The inner core

The core gives the gloves higher cut levels. For example, a Kevlar® glove has level 2 cut resistance, but it can reach level 4 when combined with a core fabric. This fabric can be from many different materials, such as fiberglass, steel, basalt, or a blended material.

But core materials can break as gloves wear, causing microscopic pieces to poke through the outer wrap. This can lead to contact dermatitis with symptoms like redness, itching, rash, and pain.

Manufacturers have taken cut-proof gloves to the next level by removing the core and infusing the outer fibers with strengthened microparticles. These yarns are 20% lighter, more comfortable, and safer under extended use without sacrificing their resistance.

Don’t worry if you purchase safety gloves for cutting that don’t come with a core material. Their protective functions remain the same. Instead, pay attention to their cut resistance level to decide whether they fit your purpose.

What Are Cut-resistant Glove Levels?

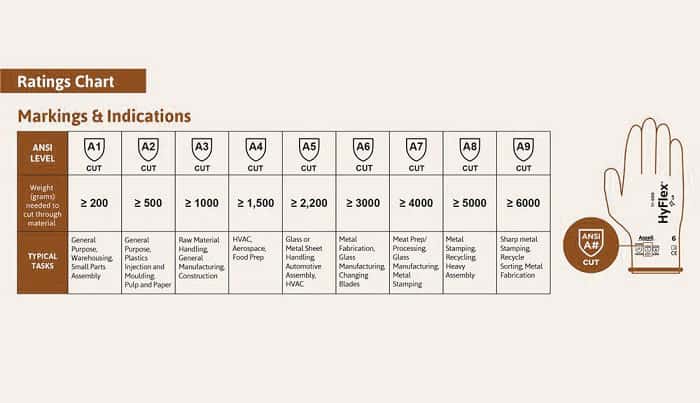

ANSI/ISEA 105-2016 (American National Standards Institute) cut resistance standard uses Tomodynamometer (TDM Method), in which a machine moves a sharp object across the glove. This object can be from 0 to 6,000 grams.

Companies look at how much weight it requires to cut the material and use this number to categorize gloves into nine levels.

Users can identify the protection level of a cut-resistant glove base on this scale. The higher the scale level, the more resistant the glove is.

Level 1 or A1 (≥ 200 grams to cut): This level offers little to no protection, only against paper cuts and light scratches. They are suitable for warehouse work, car maintenance, and other general purposes.

Level 2 or A2 (≥ 500 grams to cut): These gloves are for minimal hazards and cuts in light construction work, automotive assembly, and packing or delivering jobs.

Level 3 or A3 (≥ 1,000 grams to cut): Level 3 gloves protect against medium cut hazards. Use them when handling glass and stamping metals.

Level 4 or A4 (≥ 1,500 grams to cut): Level 4 gloves are often used in food prep, in which wearers have to work with sharp knives at a fast pace.

Level 5 or A5 (≥ 2,200 grams to cut): A5 gloves address heavy-duty protection and are preferable by meat butchers. You can rely on them to prevent cuts from sharp blades.

Level 6 to 8 (A6 ≥ 3,000 grams, A7 ≥ 4,000 grams, and A8 ≥ 5,000 grams to cut): When dealing with severe cut hazards, you can trust A6, A7, or A8 gloves. They are critical for jobs like heavy construction, rigging, ironworking, and mining.

Level 9 or A9 (≥ 6,000 grams to cut): This level is for extreme cut hazards or dangerous environments, such as heavy metal fabrication, direct contact with treacherous materials (e.g., glass, metal, wood, wire, heavy rope), and blade handling.

Choosing the highest level of cut resistance doesn’t mean maximal safety. You need to consider the dexterity, comfort, and other risks at work. Sacrificing comfort for more cut protection is not wise. Fatigued hands and tiredness are also common causes of cut accidents.

Besides the benefits, cut-resistant gloves come with many limitations. Understanding them will help you use these gloves appropriately.

Limitations

- Cut-resistant gloves are not uncuttable gloves. They won’t protect against powdered blades, such as chainsaws, drills, and grinders.

- Gloves that have high resistance ratings tend to be more rigid and heavy. The bulkiness makes them prone to being caught in running machines.

- Gloves to protect from knife cuts won’t prevent a puncture injury. Cut-resistant gloves and puncture-resistant gloves work differently.

- Employers should provide other safety means besides cut-resistant gloves to protect workers. Gloves should never be the only barrier against severe hazards.

Conclusion

In 2020, alone in the abrasive product manufacturing field, the U.S Bureau of Labor Statistics reported a total of 1,176,340 workplace injuries, 74,410 of which involve cuts, lacerations, and punctures. By educating yourself on the working mechanism of cut-resistant gloves, you are turning your working environment into a much safer place.

Don’t let safety hazards sneak up on you and the ones you love, share this article on how do cut-resistant gloves work to spread the knowledge. You can also send us thoughts and questions via the contact page. We reply to every message we get. Thank you for reading!

Veronica is our content editor. She is a talent in delivery. Her main work is editing and writing articles that are both informative and simple to follow. She is in charge of synthesizing our understanding of what personal protection equipment (PPE) is needed in each job, how to best apply it, and how to visualize that equipment.