Colors do not only make the world less boring, they possess powers that can change or affect someone’s thoughts, behaviors, and emotions.

Therefore, colors play an important role in several industries, such as construction and healthcare. They improve visibility and contrast, making objects easier to see and reducing the risk of accidents.

But among the several colors used for safety, yellow and green are the ones commonly used. However, there have been debates surrounding safety green vs safety yellow.

In short, they can be the same thing, thus interchangeable. But different manufacturers can call them by different names, and they can be used for various purposes sometimes.

Table of Contents

Safety Green vs Safety Yellow

Between safety yellow vs safety green, the difference is not much. We can actually say they are basically the same in terms of high visibility.

Still, it’s important to first define what safety colors are and why they matter.

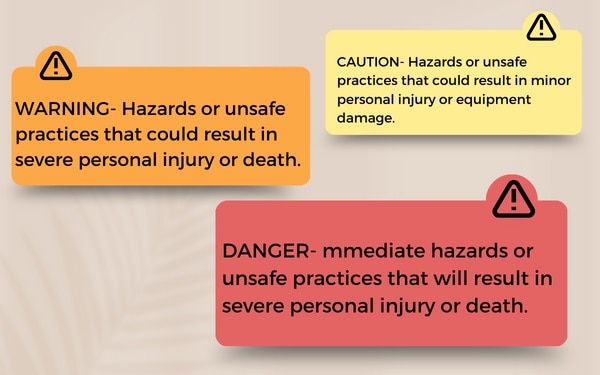

Safety colors are those specified by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These two groups have established several safety colors to ensure uniformity in visual communication across workplaces in the United States.

1. OSHA Safety Colors

The safety colors prescribed in OSHA Standard 1910.144 are used to alert individuals to particular workplace hazards and to identify safety equipment and designated safety areas.

OSHA’s mandated color chart has two colors: red and yellow.

- Red– must be used in identifying fire protection equipment and apparatus, flammable liquid containers, danger signs, stop buttons and switches, and other fire-related hazards.

- Yellow– denotes “caution” for physical hazards that may result in physical injuries, whether minor or serious.

Additionally, in its Standard 1910.145, OSHA recommends the use of additional colors to be used in marking the following prevention tags.

- Danger Signs– red, black, and white color combination.

- Caution Signs- yellow background with black panel and lettering.

- Safety Instruction Signs- white background, green panels and text

- Slow-Moving Vehicle Emblem– yellow-orange for the triangle, and red for the border.

2. ANSI Safety Colors

Unlike OSHA safety yellow and red color coding, the color coding suggested by ANSI is not mandatory. However, this standard is widely observed all over the world.

- Red– signifies danger or the need to stop

- Orange– warns of dangerous parts on machinery or equipment

- Yellow- indicates caution for various hazards

- Green– alerts people to emergency egress and locations of safety equipment

- Blue– provides information about a specific item or location

- Black and white– used for guiding traffic or direction and improving housekeeping practices

- Purple– reserved for future use by ANSI, but commonly used for radiation hazards

- Gray– also reserved for future use by ANSI.

3. High Visibility Colors

While it seems that the color codes prescribed by OSHA and ANSI have clearly distinguished safety green vs safety yellow, it’s hard to tell them apart in the world of high visibility colors, also known as hi vis colors.

Colors are considered high visibility if they possess fluorescent qualities that make them emit light when exposed to sunlight or ultraviolet light.

| Hi-vis color | Luminance level (%) |

| Red | 25 |

| Orange | 40 |

| Green | 70 |

Fluorescent colors are also known as neon colors.

- Therefore, fluorescent safety yellow and safety yellow can be called neon yellow and neon green when used in construction reflective shirts and other apparel.

- The reason for all of the confusion between the two colors is because there is not not much of a difference between neon yellow vs lime green or neon green, and any person may see these colors as “the same”.

- This is why when it comes to neon yellow vs neon green, both colors are often interchangeable, and that manufacturers have the freedom to label either color as they see fit. Thus, your neon green construction shirts and neon green work shirts may look like neon yellow for others.

But what are the other high visibility colors?

Understanding safety vest colors meaning is crucial in determining the appropriate hi vis apparel for your work environment.

Designed to enhance your visibility and prevent accidents and injuries, each hi vis apparel uses colors that “stand out”. There are three most common fluorescent, safety shirt colors.

- Yellow-Green

Fluorescent yellow-green is the most visible color according to ANSI standards. High-visibility clothing of this color is commonly worn by roadway workers because it contrasts with the orange used in traffic cones and signs. Thus, fluorescent safety green clothing is deemed effective when working in high-speed traffic areas.

Fluorescent yellow-green also stands out in urban environments where neutral colors are prevalent, making workers more noticeable. However, workers in natural or green environments tend not to wear this color due to its greenish tint.

- Orange-Red

Fluorescent orange-red is another common color for hi-vis safety clothing, which aims to trigger the same response as orange traffic cones or signs.

This color is often seen on construction sites because it stands out and makes workers more visible around heavy machinery. However, it is not commonly used among roadway workers because it can be mistaken for an inanimate object by fast-moving drivers.

- Red

Although a newer addition to ANSI standards, fluorescent red is already commonly used in some European countries for safety clothing.

This color is particularly useful when workers operate in low-light conditions, such as around dawn or dusk, as it stands out and attracts our attention much faster than other colors.

However, to ensure optimal visibility, fluorescent red should be paired with sufficient reflective material.

Frequently Asked Questions

Are safety vests green or yellow?

Safety vests can be in yellow and safety green. The former is for traffic control and crossing guards. Meanwhile, the latter is for landscaping and surveying tasks.

What is the best safety color?

It could be said that orange vs yellow are candidates for this position. In fact, fluorescent yellow might be the strongest safety color as it’s the brightest regarding the luminance factor. However, safety vests made of orange color will have a higher impact on warning of dangers.

Classification of High Visibility Apparel

It is also important to consider if your fashionable hi vis clothing or neon construction shirt and apparel meets the required specification for engineers, construction workers, and other industry workers.

| Safety Vest Class | Recommended Workers | Minimum Reflective Tape Measurement | Traffic Flow | Reflective Stripes Placement |

| Class 1 | Parking attendants, delivery drivers, roadside assistance personnel | – 155 sq. in.

– 6.46 linear feet of 2-inch tape or 9.39 linear feet of 1 3/8-inch tape |

Not exceeding 25 mph | A 360º stripe around the middle and above each shoulder. |

| Class 2 | Airport workers, high-volume parking or toll booth operators, forest workers | – 201 sq. in.

– 8.373 linear feet of 2-inch tape or 12.2 linear feet of 1 3/8-inch tape |

May exceed 25 mph

|

One or two horizontal stripes that go 360º around the middle and over the shoulders. |

| Class 3 | Site inspectors, emergency responders, railway workers, utility crews | – 310 sq. in.

– 12.92 linear feet of 2-inch tape |

Exceeding 50 mph | The vest must have reflective materials on the arms and legs in addition to a full silhouette outline. |

Click here to know about the details of class 1, 2, and 3 safety vests!

Conclusion

Learning the difference of safety green vs safety yellow, as well as the use of other safety colors will help you identify and understand hazards, safe areas, and how to use them to alert people to the presence of potential dangers.

Without safety colors, people would be exposed to various hazards, and accidents could occur more frequently, resulting in injuries, fatalities, or property damage. Therefore, understanding the importance of safety colors and using them appropriately can help ensure a safer environment for everyone.

Veronica is our content editor. She is a talent in delivery. Her main work is editing and writing articles that are both informative and simple to follow. She is in charge of synthesizing our understanding of what personal protection equipment (PPE) is needed in each job, how to best apply it, and how to visualize that equipment.