For craftsmen, carpenters, electricians, and DIY enthusiasts, a leather tool belt is a must-have accessory to contain tools and equipment needed for their tasks.

However, just like any other accessories made of leather, it can be stiff for several reasons. For one, new leather is naturally stiff and has to be broken in order to be used properly. It can also harden if it is not well-maintained or stored.

Whatever the reason, the bottom line is: nobody deserves to be working with a stiff tool belt. So keep on reading to learn how to soften a leather tool belt.

Table of Contents

Ways to Soften Leather Tool Belt

In the following steps, you will learn the methods to soften hardened leather tool belts using D.I.Y. (petroleum jelly and natural oils) and store-bought leather care products. However, before going through each method, make sure that your accessory is already cleaned before proceeding with the softening process.

You will need the following materials:

- Rubbing Alcohol

- Petroleum jelly (i.e. Vaseline)

- Cotton balls or tissue paper

- Clean cloth

Here are the steps:

Step #1: Apply rubbing alcohol.

Put an adequate amount of rubbing alcohol onto a cotton ball or a piece of tissue paper.

Once the cotton or tissue is soaked in alcohol, rub it onto the surface of the tool belt. Make sure to apply a generous amount in order to open up the fibers and pores of the leather.

Step #2: Condition with petroleum jelly.

With your fingers, take an ample amount of petroleum jelly and spread it all over the tool bag’s surface.

Leave it on for a few minutes until it is fully absorbed by the leather.

Petroleum jellies, like Vaseline soften leather as they contain oils that moisturize and nourish the leather.

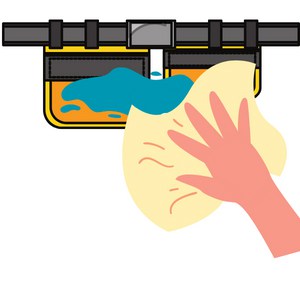

Step #3: Wipe off the excess petroleum jelly.

Use a clean cloth or rag to remove excess petroleum jelly off the tool belt. Once done, allow it to dry overnight.

To soften a leather belt for tools using natural oils, you will need the following materials:

- Natural oil of choice (e. lanolin, mink, or neatsfoot oil)

- Clean Cloth (optional)

Step #1: Rub the oil onto the leather.

When choosing a natural oil to soften a leather tool pouch, you have to make sure that they will not damage the leather.

For this step, you can use either a clean cloth or just your fingers. Take a good amount of oil and rub it all over the leather’s surface.

You can repeat this step as needed until the leather begins to soften.

Step #2: Let it dry.

The duration of the drying process will depend on the kind of oil that you will use. For example, when using mink oil, it is suggested to wait two to three days for it to completely dry.

When drying your tool belt, it is best to keep it away from dust so it won’t stick to the leather.

Leather conditioners are packed with ingredients that are beneficial for the nourishment of the leather. To use this to soften leather bag for tools, you will need the following materials:

- Leather conditioner

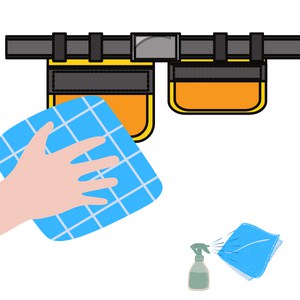

- Clean, soft cloth (lint-free)

Step #1: Get a sufficient amount of leather conditioner onto a clean, soft, and lint-free cloth.

Step #2: Spread the product evenly all over the leather’s surface.

An uneven application will make it look patchy as it dries.

A good rule of thumb is to apply multiple, thin coats of leather conditioner instead of a single, thick layer. Make sure to let the product dry between each coat.

Repeat this step as necessary. You should end up with a soft, polished and healthy-looking leather tool bag.

You can always use this method to soften leather pouches and tool bags.

The Importance and Benefits of Softening Leather Tool Belt

If you’re thinking that softening a leather tool belt is all about being picky about the accessory’s overall texture and feel, you are wrong. There is a whole point behind the whole process.

Here are the reasons why it is important and beneficial:

1. It keeps the leather healthy and lengthens its life.

2. The softened leather reduces the risk of injuries and pain around the waist.

3. Maximizes the durability and flexibility of the leather.

When Should You Soften Your Leather Tool Belt

If you’re not sure when is the best time to soften your tool belt, here are the indicators that you need to consider:

1. If you’ve used them for a long time.

With prolonged use, there is a high chance that your leather tool belt can become stiff. It is also good to note that if the leather is already old, it is more prone to hardening as it is most likely stripped off of its natural oils.

2. If there are visible damages.

Peels and damages are just like wounds that need to be treated immediately as they can worsen when left untreated. That being said, seeing those calls for a good leather softening session!

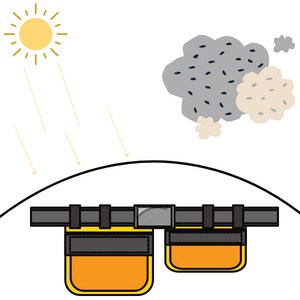

3. If used outdoors

Using your tool belt outdoors exposes it to weather conditions that can cause damage to the leather— sun, rain, and dust. So to keep your trusty accessory in best condition, develop a good habit of checking it after using them outdoors and see if they need to be softened.

Tips in Conditioning a Leather Tool Belt

Tip #1: Do not expose your tool belt near excessive heat.

Tip #2: Do not over-saturate the leather with conditioners.

When it comes to applying leather conditioners, people may think that “the more, the better”. However, this is not always the case. Adding too much conditioner will oversaturate the leather.

In this case, the leather will absorb unnecessary moisture and may end up becoming too soft, too dark, and even sticky.

Tip #3: When using commercial leather tool belts, always make sure to check the instructions provided by the manufacturers. After all, leather conditioners are not created equal and some may require special handling or application instructions.

Frequently Asked Questions

FAQ #1: Why does my tool belt hurt my hips?

When you wear your tool belt and store your tools in it, you are basically resting the tools’ entire weight on your waist and hips. This will cause you to feel pain and strain on the said areas.

But aside from weight, tool belts can also cause pain when it becomes stiff and the leather starts pinching your skin.

FAQ #2: How do I break in a new leather tool belt?

Breaking in a leather tool belt is almost similar to softening it. However, if you want to speed up the process, it is advised to put some of your heavy tools inside the pockets during the drying process. The weight of these tools will help in stretching the new leather tool belt and improve its flexibility.

FAQ #3: What oils can I use to soften my tool belt?

Generally, you would want to choose natural oils that can effectively moisturize the leather. Some of these oils include neatsfoot, almond, lanolin, and mink oils.

If you want to quickly soften your tool belt, you may choose neatsfoot oil. However, it should be used moderately as it can damage the leather in the long run.

For tougher leather, you may choose lanolin as it can deeply penetrate its fibers. On the other hand, you can use mink oil if your tool belt has dried up badly. Mink oil is effective in replenishing stripped oil.

However, it is good to note that some natural oils can darken leather after several applications. In example, mink oil is said to darken leather for about 2-3 shades darker. Unless you really want to alter the color of your tool belt, you may want to reconsider using natural oils.

Conclusion

Whether you’re a professional or a D.I.Y. enthusiast, a tool belt is surely one of your best companions when doing work. And that being said, it should be taken care of so you may use it for a longer time.

The steps on how to soften a leather tool belt are relatively easy, and considering the number of methods that you can use, there’s no reason why you should struggle in using a dry and stiff accessory.

Keeping your tool belt soft and well-maintained requires consistency. After all, the best way to soften leather tool belt is to do it regularly.

Veronica is our content editor. She is a talent in delivery. Her main work is editing and writing articles that are both informative and simple to follow. She is in charge of synthesizing our understanding of what personal protection equipment (PPE) is needed in each job, how to best apply it, and how to visualize that equipment.