Gone are the days when workers only wore safety belts to arrest falls. Now, the US Occupational Safety and Health Administration (OSHA) requires all employers to provide their employees with fall protection equipment when working at a height.

When it comes to the minimum height to wear safety harness, the standards differ depending on the job. Let’s take a look at the finer points of these OSHA rules.

Table of Contents

The No Minimum Height Rule

The “No Minimum Height Rule” is a provision that requires employees to use fall protection if they are at risk of falling on sharp objects, hazardous machinery, or rebars, even while they are on ground level.

Minimum Height for Fall Protection for Different Jobs

So, fall protection is required at what height?

Based on OSHA’s ruling, employers that fall under “General Industry” must provide their employees with fall protection when working above 4 feet or 1.2 m in meters. In the construction industry, fall protection is required when the height or fall is over 2.0 m or 6 feet.

Keep in mind that there are exceptions to these height requirements:

1. Climbing Vertical Rebar Assemblies

Employees don’t need fall protection when climbing less than 24 feet high on a vertical rebar assembly, but this does not mean you can ditch your harness altogether.

When is a safety harness required in this situation?

The use of harnesses, lanyards, and positioning devices is a must if:

- The worker needs to climb at least 24 feet.

- The worker has reached his workstation.

2. Scaffolding

Workers must use personal fall arrest systems (PFAS) or guardrail systems as protection when working on scaffolds above 10 feet.

However, each type of scaffolding has specific requirements:

- Suspension scaffolds

Workers must use either a PFAS or a guardrail system if the suspended scaffold is over 10 feet above the ground. When on single-point and two-point adjustable scaffolds, however, the use of both PFAS and guardrails is mandatory.

- Supported scaffolds

Either a PFAS or guardrails will suffice on scaffolds like these.

- Airlifts, boatswain’s chairs, catenary, ladder jack, needle beam, and float scaffolds

Employees are required to use a PFAS.

- Self-contained adjustable scaffolds supported by ropes

For this type of scaffolding, both PFAS and guardrails are needed.

- Crawling board scaffolds

Aside from PFAS or guardrails, employers may also set up a grabline or handhold for crawling boards. These structures should be ¾ inch in diameter.

- For other types that are not mentioned above

Workers may use either a PFAS or a guardrail system.

3. Stairs and Ladders

1. Stairs

OSHA stipulates that stairwells with at least four risers must have a handrail and a guardrail. The handrail should have handholds, while guardrails should be on the exposed sides of the landings. The same applies to stairways higher than 30 inches.

2. Ladders

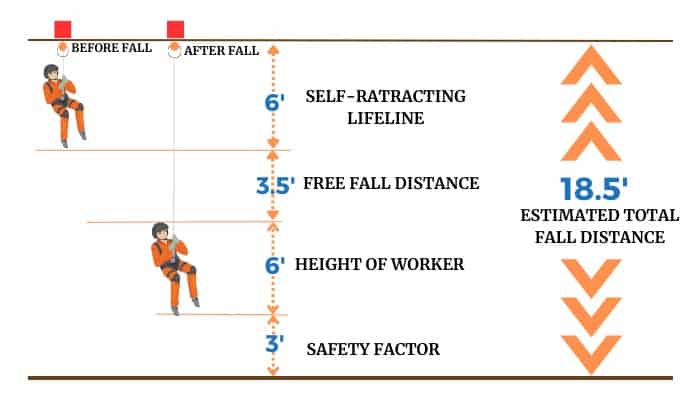

According to OSHA working at height of more than 24 feet means workers should use self-retracting lifelines or ladder safety devices.

Likewise, fall protection is needed if the worker is on a ladder shorter than 24 feet but its climb exceeds this height.

For extension ladders, take note of these provisions:

- The ladder’s extension must exceed 3 feet of the surface that you intend to reach.

- The ladder must maintain a 4:1 rise-to-run ratio. In other words, the base of the ladder should be positioned 1 foot away from the structure each time it extends four feet.

- The worker must follow the three-point rule, ensuring that either both legs and one hand or both hands and one leg are used to climb. Therefore, the employee must not carry buckets or other tools when moving up the ladder.

4. Steel Erection

The safety height requirements for steel erection are a little complicated, but let’s make them easy to digest.

Generally, fall protection is only needed if the employees reach 15 feet above the ground. However, exceptions apply to connectors, for whom the rules are outlined below:

- 30 feet – No tie-offs

- Two 12-feet floors – Tie-offs may be necessary

- One 24-feet floor – No tie-offs

- Over 15 feet – anchorage and fall protection required

OSHA Rules

The goal of OSHA’s fall protection height regulations is to minimize, if not eliminate hazards. Regardless of the industry, employers must ensure that the workplace is clean and safe, and that all employees are provided with fall protection equipment and safety training.

Conclusion

Considering all the rules and exceptions for each situation, the guidelines on minimum height to wear safety harness can be very confusing and difficult to remember at first. But this should not be a reason to violate OSHA standards. The risks are simply too high—you either pay the fines, cause an accident, or both.

Although the employers are the ones who are required to provide everything that the employee needs to work safely, both parties should know when to use the appropriate fall protection equipment.

Veronica is our content editor. She is a talent in delivery. Her main work is editing and writing articles that are both informative and simple to follow. She is in charge of synthesizing our understanding of what personal protection equipment (PPE) is needed in each job, how to best apply it, and how to visualize that equipment.